Introduction

Steel solar racking systems are widely used in utility-scale photovoltaic (PV) projects due to their high strength and relatively low upfront cost. However, in desert environments, many EPCs and project owners begin to encounter unexpected corrosion and maintenance issues only a few years after commissioning.

This raises a critical question for long-term project performance:

When does steel solar racking actually start corroding in desert PV plants — and why does it happen faster than expected?

Why Desert Environments Accelerate Steel Corrosion

Desert regions are often considered “dry” and therefore low-risk for corrosion. In reality, deserts combine multiple aggressive factors that accelerate material degradation:

1. Extreme Temperature Cycles

Daily temperature swings of 30–40°C create repeated thermal expansion and contraction, which weakens protective coatings and creates micro-cracks on steel surfaces.

2. High UV Exposure

Intense UV radiation degrades paints, galvanization layers, and surface treatments over time, reducing corrosion protection effectiveness.

3. Sand Abrasion

Wind-blown sand acts like continuous sandblasting, gradually wearing away zinc layers and exposing bare steel.

4. Hidden Moisture and Salts

Even in arid regions, night-time condensation, occasional rain, or saline dust (especially near coastal deserts) can introduce moisture that initiates corrosion once steel is exposed.

Typical Timeline: When Corrosion Begins Based on field observations from large-scale desert PV projects

Year 0–2: Steel structures appear intact; corrosion is rarely visible

Year 3–5: Coating degradation begins, especially at joints, bolts, and cut edges

Year 5–8: Visible corrosion spots emerge; maintenance frequency increases

Year 8+: Structural degradation accelerates, increasing O&M cost and long-term risk

At this stage, corrosion is no longer a cosmetic issue — it can affect structural integrity, grounding reliability, and system safety.

Why Traditional Protection Methods Fall Short

Common mitigation methods include:

Hot-dip galvanization

Additional painting or coating

Thicker steel sections

While these approaches can delay corrosion, they do not eliminate the root cause. Once protective layers are damaged, steel remains inherently vulnerable in harsh desert conditions.

Moreover, repairs in operating solar plants often mean:

Increased labor cost

Safety risks

Potential downtime

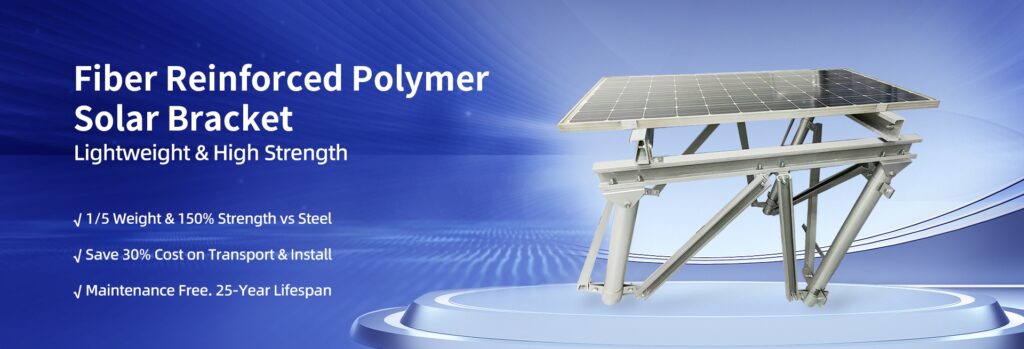

An Alternative Approach: Corrosion-Free Structural Materials

To address long-term corrosion risk, some EPCs are now evaluating non-metal structural materials, such as FRP (Fiber Reinforced Polymer) solar mounting systems.

Key characteristics include:

Zero corrosion (no oxidation reaction)

UV-resistant material formulations

No galvanization or repainting required

Stable performance under sand abrasion and temperature cycling

These properties make FRP structures particularly suitable for desert, coastal, and high-UV solar projects.

When Does a Corrosion-Free Solution Make Sense?

Corrosion-resistant alternatives are not always necessary for every project. However, they become highly relevant when:

Project lifetime is 25–30 years

O&M access is limited or costly

Sites are located in desert, high-UV, or corrosive regions

EPCs aim to reduce long-term risk rather than initial CAPEX only

In such cases, evaluating lifecycle performance — not just upfront material cost — becomes critical.

Conclusion

Steel solar racking does not fail immediately in desert environments, but corrosion often begins much earlier than expected, typically between year 3 and year 5, driven by UV exposure, sand abrasion, and temperature cycling.

For utility-scale desert PV projects, understanding this timeline is essential when selecting mounting structures that align with long-term reliability and cost control goals.

Learn more about solar mounting solutions designed for desert environments and how EPCs are reducing lifetime risk through material innovation.