Fiber Reinforced Polymer (FRP) Solar Mounting System

— Future of Solar Racking: Lighter Than Aluminum, Stronger Than Steel

Ideal for Roof, Desert & Offshore Zones

Next-Gen Solar Mounting Technology

As high-performance advanced material, Fiber Reinforced Polymer (FRP) is outstanding option for solar brackets, to replace steel and aluminum alloy.

Fiber Reinforced Polymer Solar mounting system is lightweight, high-strength with corrosion resistance, electrical insulation and aging resistance.

FRP is made by restructuring multi-element nano crystal grains into a unified structure, thus greatly enhancing mechanical and chemical performance. FRP has been widely used in aviation, marine, power generation, chemical, and construction industries.

Key Advantages

- Lightweight and High strength:

Weighs only 1/5 of steel brackets, while 150% of the strength.

- Excellent Chemical Stability:

Resistant to corrosion, aging, and oxidation.

- Superior Electrical Insulation:

Insulation performance reaches 12 million volts.

- All-Weather Performance:

Heat and flame resistant, workable from -40℃ to 120℃.

- Self-Cleaning:

Non-scaling, water repel and low friction.

- Easy Installation and Maintenance Free

25-year lifespan with few Save 40% on transport and labor costs.

Why FRP Outperforms Metal Brackets?

- MarineEnvironment (Perfectly solve rust problem)

- DesertEnvironment (Resist sand erosion and coating damage )

- Electrical Safety (No grounding needed.No metal oxidation)

- Economic Benefits(Lower transport & install cost. Save 0.02-0.04RMB per watt in the usage.)

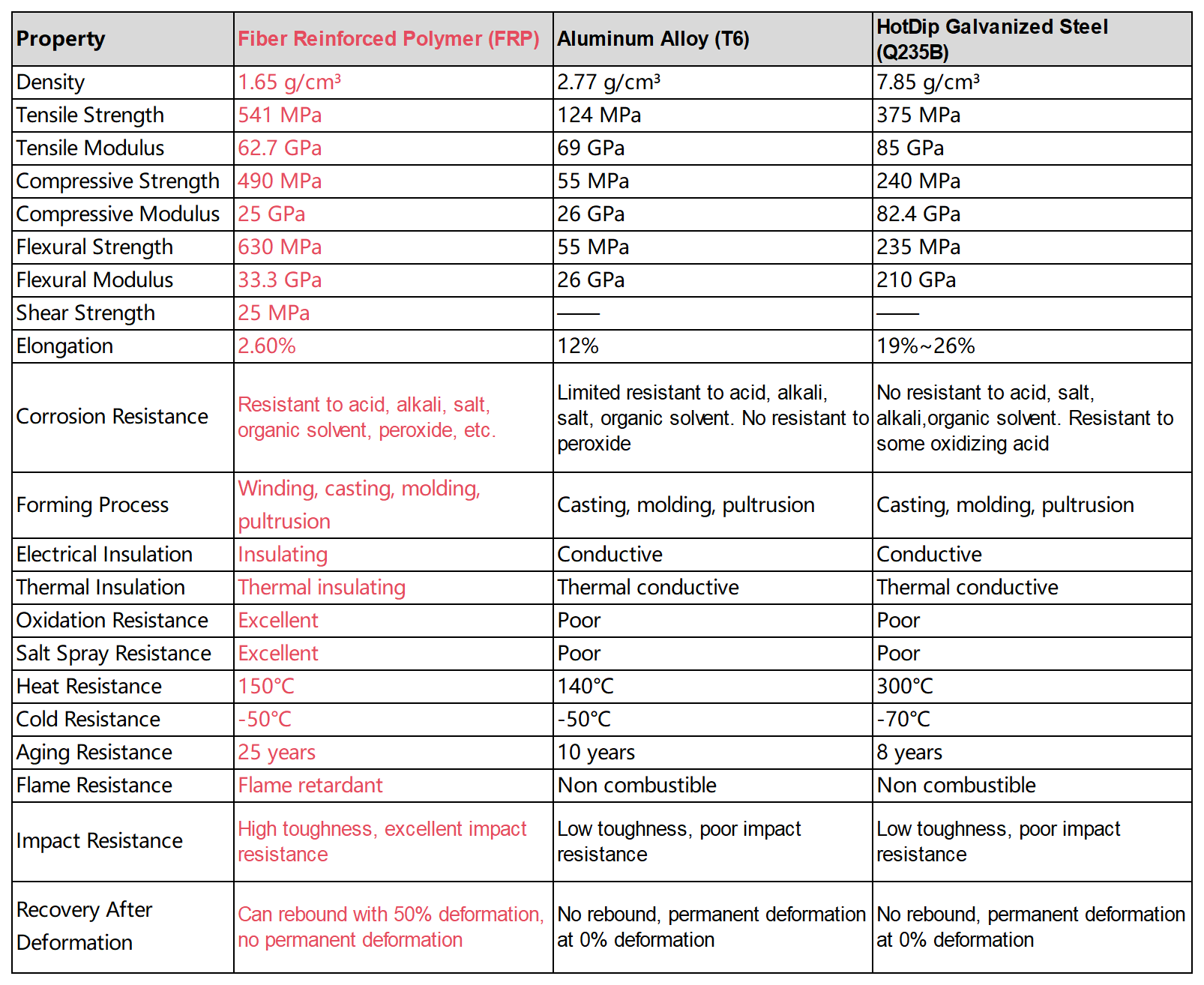

Material Performance Comparison

Have a Great Advantage

V.s. Aluminum Alloy

V.s. Hotdip Galvanized Steel

Ready to Upgrade Your Solar Project?

Contact our engineering team for a cost-benefit analysis today!