As hurricanes, wildfires, and temperature extremes become more frequent, solar assets face unprecedented risks. Traditional steel and aluminum solar racking—vulnerable to corrosion, fatigue, and thermal stress—struggles to provide the resilience modern projects demand.

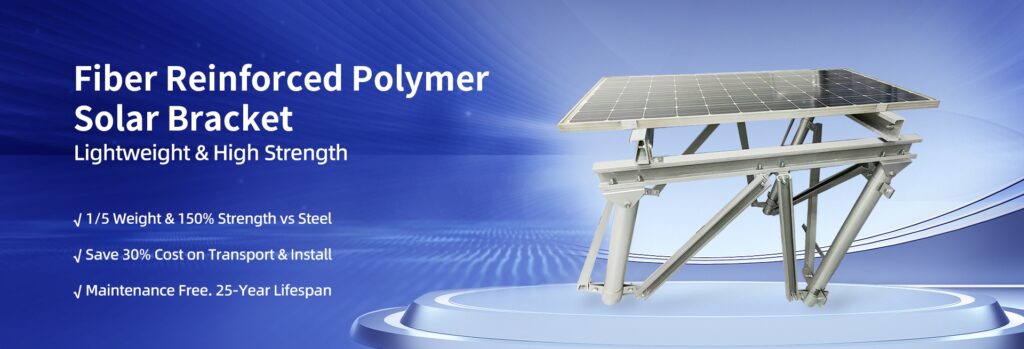

Advanced Fiber Reinforced Polymer (FRP) composite solar stand offers an engineered solution, addressing multiple climate threats in one system. Its core advantage is an exceptional strength-to-weight ratio; being up to 75% lighter than steel drastically reduces wind load forces on foundations during storms. Unlike metals, FRP is inherently corrosion-proof, surviving salt spray, floodwaters, and acidic atmospheres without coating or rust. For wildfire-prone areas, its non-conductive and flame-retardant properties add a critical layer of safety. Furthermore, its low thermal expansion coefficient prevents stress and micro-cracking in panels during intense heat waves or rapid freeze-thaw cycles.

The result is a fundamentally more durable asset. By eliminating corrosion-related maintenance, preventing storm-related deformations, and avoiding temperature-induced failures, composite solar mounting system ensures uninterrupted energy production and delivers a lower Total Cost of Ownership over a project’s 25+ year lifespan.

For developers and EPCs, this translates from vulnerability to resilience. Building solar farms that can withstand what’s coming is no longer a hope—it’s an engineering decision.