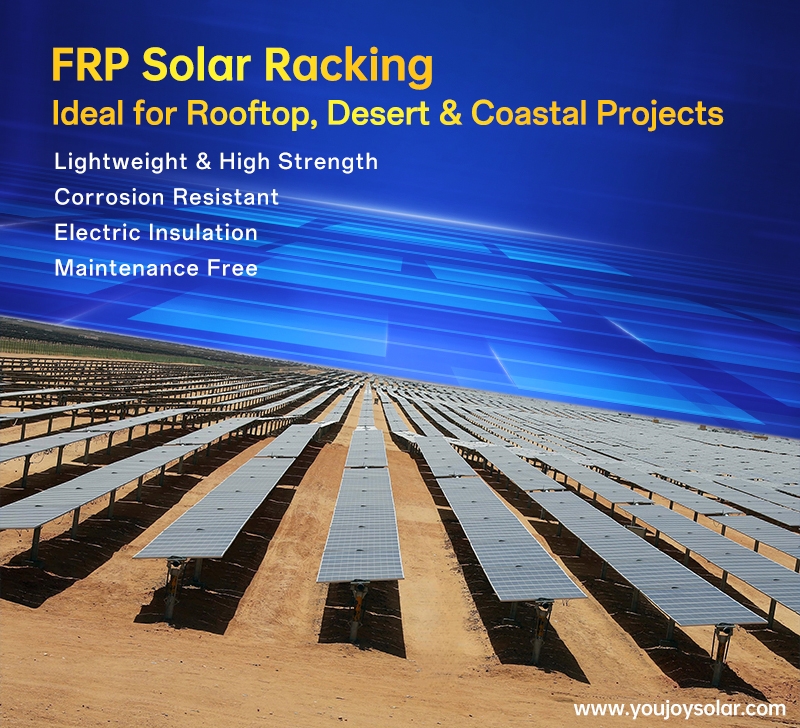

Metal solar racking’s inherent conductivity creates dangerous electrical pathways that compromise system safety and increase project risks. FRP composite racking provides a comprehensive solution that eliminates these conductivity issues through built-in electrical insulation.

Metal Racking Conductivity Challenges:

~Creates unintended ground fault pathways through structural components

~Increases lightning strike attraction, risking equipment damage

~Requires complex and expensive grounding system installations

~Poses continuous safety risks during maintenance operations

FRP Composite Insulation Solution:Our non-conductive racking delivers complete electrical safety:

- 1000V+ Dielectric Strength: Built-in insulation prevents current leakage and ground faults

- Grounding System Elimination: Removes need for complex grounding networks

- Lightning Risk Reduction: Non-conductive material minimizes strike attraction

- Maintenance Safety: Complete protection against electrical shock hazards

Concrete Implementation Benefits:For EPC contractors facing conductivity challenges:

- 60% cost reduction in grounding system components and installation labor

- 40% faster commissioning through simplified electrical design approval

- Zero ongoing maintenance for electrical safety verification

- Eliminated liability from electrical incident risks

Compliance and Certification Assurance:

- Full compliance with IEC 62548 photovoltaic system safety standards

- UL 2703 certification for mounting system electrical safety

- Third-party verified 1000V+ dielectric strength testing

- Meets all international electrical codes and safety regulations

Documented Performance Evidence:From 500+ MW installed capacity across diverse environments:

- Zero electrical safety incidents in high-humidity coastal installations

- 100% successful safety inspection approvals in industrial zones

- Simplified operation and maintenance procedures with reduced documentation

- Eliminated corrosion-related electrical degradation over time

Immediate Solution Implementation:[Download our Electrical Safety Assessment Toolkit] for comprehensive risk analysis and solution comparison specific to metal conductivity issues. [Request Customized Insulation Solution Plan] tailored to your project’s specific electrical safety requirements. [Schedule On-Site Safety Audit] to identify and eliminate conductivity risks in your current or planned installations.

Technical Specifications:

- Dielectric strength: >1000V (third-party verified)

- Surface resistance: >10¹² ohms (prevents current leakage)

- Lightning protection: Non-conductive properties reduce strike probability by 70%

- Maintenance requirements: Zero electrical safety checks needed